embodied carbon

What is embodied carbon?

Embodied carbon is the measurable greenhouse gas emissions of an infrastructure's entire construction, maintenance and demolition processes. Unlike operational carbon, which measures a structure's emissions based on energy use during its occupancy, embodied carbon provides that structure's carbon footprint strictly outside of its functional phase.

Each manufacturing and processing stage of a new structure -- an under-construction house, building or road -- contributes to greenhouse gas emissions. Deconstruction practices, such as waste material transport, recycling and disposal of a demolished structure, likewise release greenhouse gases at the end of the structure's life cycle. These aspects of a structure's overall carbon footprint are also, at times, mischaracterized and misunderstood.

The term carbon in embodied carbon refers chiefly, but not exclusively, to the emission of its famous compound, carbon dioxide (CO2). Embodied carbon's makeup includes methane, nitrogen oxide, sulfur hexafluoride and others, though CO2 accounts for 79% of all greenhouse gas emissions, according to the Environmental Protection Agency.

Why understanding embodied carbon is important

In the pursuit of environmental sustainability, the protection of the ozone layer is crucial, as greenhouse gas emissions contribute to both climate change and ozone depletion. The significance of embodied carbon in construction and design creates a global impact, particularly in developing nations.

Ozone layer protection

Greenhouse gas emissions are, in general, responsible for climate change and can deplete the ozone layer, which offers protection from the sun's UV radiation. Embodied carbon emissions cause fluctuations in ozone concentrations, resulting in increased pollution, crop damage and other health-related problems.

Green designs

Embodied carbon is critical to understanding the overall environmental impact of ubiquitous building materials like cement, aluminum, steel and glass. Accurately estimating embodied carbon in the design stage is critical for a project's sustainability. All architects, builders, contractors and construction industry professionals who champion sustainability must demonstrate eco-friendly practices and forethought.

Global issue

Embodied carbon is indeed a developing world problem. Buildings currently account for 39% of total global energy-related carbon emissions, including 11% from embodied carbon. As the real estate industry continues to expand worldwide, embodied carbon emissions of developing nations, those trying to play catch-up in the energy race, are increasing at higher rates than already industrialized nations.

Embodied carbon calculations

Life cycle assessments calculate an infrastructure's total carbon emissions, both embodied and operational carbon, throughout its development, use and any needed maintenance and deconstruction stages.

Carbon is emitted during the following stages:

- During construction.

- During a structure's use.

- During a structure's demolition.

The carbon factor of the building life cycle is measured and provides an updated emissions estimate. A material's embodied carbon value is its quantity, measured in kilograms, multiplied by its carbon factor, usually expressed in kilogram of carbon dioxide equivalent per kilogram (kg CO2eq/kg). Note that embodied carbon is the amount of emissions during construction and demolition only.

Depending upon measurement practices, carbon factor can also be expressed in kg CO2eq/kg per square or cubed meter (kg CO2eq/m2 or kg CO2eq/m3).

Regardless of how it’s expressed, CO2eq compares various greenhouse gases based on their global warming potential (GWP). The GWP converts other greenhouse gases into carbon dioxide equivalent for a more complete measurement of an infrastructure's embodied carbon.

The formula to calculate embodied carbon becomes one of the following:

- Embodied carbon = kg × kg CO2eq/kg.

- Embodied carbon = kg CO2eq.

Embodied carbon contributors

Embodied carbon emissions accumulate throughout a structure's life cycle, from raw materials extracted and transported for construction to their reuse and disposal as part of demolition. The initial stages of embodied carbon release are listed below.

Raw material extraction and transportation

The extraction of raw materials such as iron ore, sand, limestone and other ores, especially those using non-renewable energy sources, pollutes the environment. The creation and use of carbon-intensive materials -- common materials such as concrete and brick -- add significantly to a structure's embodied carbon emissions.

In addition, the distance these raw materials must travel to reach the manufacturing unit impacts greenhouse gas emissions.

Manufacturing

Once in the factory, chemically and mechanically processing raw construction materials and various production procedures release carbon dioxide. Cement and concrete produce nearly 9% of all human CO2 emission globally.

Transportation, construction and installation

Processed materials then continue their journey to the actual construction site. Each form of transport adds to CO2 emissions.

After transportation, construction begins on site. Installation of steel into frames and glass into doors and windows further contributes to embodied carbon emissions.

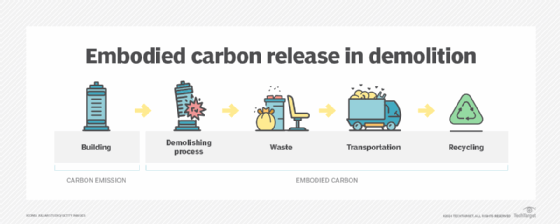

Most additional embodied carbon emissions stem from the structure's eventual demolition and its subsequent stages, as indicated below.

Demolition

When a building is demolished, carbon dioxide and other poisonous gases are released into the environment. The demolished waste gathers on the ground.

Transportation and waste processing

Transporting the remaining building materials to the processing unit for disposal further adds to embodied carbon release.

Ultimately, the building material waste from deconstruction is sent to a recycling hub. The recycled waste from the building is repurposed for the construction industry and textile manufacturing.

Importance of sustainable construction

Sustainable practices refer to green material selection as well as implementation of biosphere-friendly construction processes, operational maintainability, renovations and safer deconstruction processes throughout an infrastructure's lifetime.

The construction industry, recognizing the need to embrace sustainability, has set a goal of reaching net-zero carbon emissions by 2050. The industry has created several ratings and certifications that recognize sustainable building practices as well as reward forward-thinking construction and maintenance.

Green building certifications

Green building certification is allotted to buildings that adhere to life cycle assessment and sustainability practices. This certification indicates the builders opted for materials and processes that release fewer greenhouse gases.

LEED rating

The United States Green Building Council developed the Leadership in Energy and Environmental Design (LEED) rating system in the 1990s. Today, LEED goals include saving water resources, conserving biodiversity and maintaining sustainability for constructing buildings and neighborhoods.

BREEAM method

The Building Research Establishment Environmental Assessment Method (BREEAM) is a system of evaluation that provides environmental impacts of an infrastructure. BREEAM bestows one of five ratings to buildings from "outstanding" down to "pass."

Reducing embodied carbon in the material world

For sustainable construction practices, several key strategies contribute to minimizing environmental impact. Taking actions such as using green materials and implementing renewable energy processes are a few ways to reduce carbon emissions. The following are some other approaches to be more environmentally conscious in building and infrastructure development:

- Low carbon materials. Using carbon-positive materials such as sustainably harvested timber and bamboo to build an infrastructure's floors, walls, doors, windows, facades and ceilings can actually remove and store carbon throughout its existence. Using low-carbon materials also results in carbon reduction for a building.

- Green materials. The complete elimination of concrete in buildings is not possible today. One way to minimize concrete's harmful effects is to choose carbon-negative concrete.

- Carbon storage materials. Sequestering traps stores CO2 during construction procedures. Examples of these carbon storage materials include wood, bamboo, hemp and straw.

- Reuse of materials. Reusing a building or any of its components limits carbon emissions and is greener than new construction. The destruction of a building, which includes the use of bulldozers and explosions, raises local pollution levels and carbon emissions.

- Recycling of materials. After demolishing a building, the waste material is taken into the recycling hubs. Reclaimed bricks, concrete, steel and other building materials drastically reduce carbon emissions during new construction.

- Smart design with materials. Designers focused on sustainability aim to eliminate carbon-intensive construction materials and facilitate green designs. These designs typically use fewer materials and employ simple architecture.

- Renewable energy processes. Renewable energy methodologies reduce embodied carbon emissions during the extraction of raw materials. Moreover, renewable energy plays a positive role throughout the infrastructure's construction processes, maintenance, renovations and deconstruction.

Challenges and triumphs in addressing embodied carbon

Navigating the path towards sustainable construction encounters various challenges. Factors such as industrial resistance and economic constraints can collectively influence stakeholders and decision-makers, shaping the industry's approach to adopting environmentally friendly practices and materials.

Industrial resistance

Stakeholders and decision-makers are often reluctant to embrace new procedures or support the adoption and use of sustainable materials, prioritizing the immediate economic difficulties in making these changes over long-term benefits.

Lack of awareness and effort

Some industry insiders and many consumers remain unaware or uninformed about the harmful impact of construction processes on climate change. Industry lacks data to support the benefits of greener infrastructures.

Economic constraints

Low-carbon materials, sustainable practices and cutting-edge electrical equipment cost more than current construction standards. However, some governments continue to pass legislation removing financial barriers to decarbonization.

Scarcity of greener materials

Compared to concrete and other high-carbon materials, green materials for construction processes remain difficult to find or produce. This lack of availability and supply chain complexity increases project costs.

Technological advancements

The construction industry in the USA surpassed $1.8 trillion in revenue in 2022, and the market size of the construction industry is predicted to increase through 2025. Renewable energy technology reduces the embodied carbon from a building life cycle. Technological developments including prefabrication, electric machinery, CNC machining, 3D printing and robotics also reduce the carbon footprint of the construction processes.

Global collaboration

Historically, international efforts and laws banning poisonous gases such as chlorofluorocarbon, hydrochlorofluorocarbon, carbon tetrachloride and methylchloroform have successfully protected the ozone layer. Current initiatives in embodied carbon reduction aim to achieve net-zero emissions in the next 20 to 30 yearsThe Structural Engineering Institute of the American Society of Civil Engineers, World Green Building Council and various other organizations fighting climate change plan to achieve low embodied carbon by 2030 and net-zero carbon emissions by 2050.

Policy changes

Governments are providing credit for buying and manufacturing sustainable equipment and tax exemptions to encourage greener practices. In addition, some governments have added extra tax on occupied properties to discourage the construction of new buildings.

In the U.S., the Inflation Reduction Act of 2022 includes a funding amount of $5 billion to reduce the carbon footprint of the U.S. construction industry.